- Home

- Schools

- Learning material

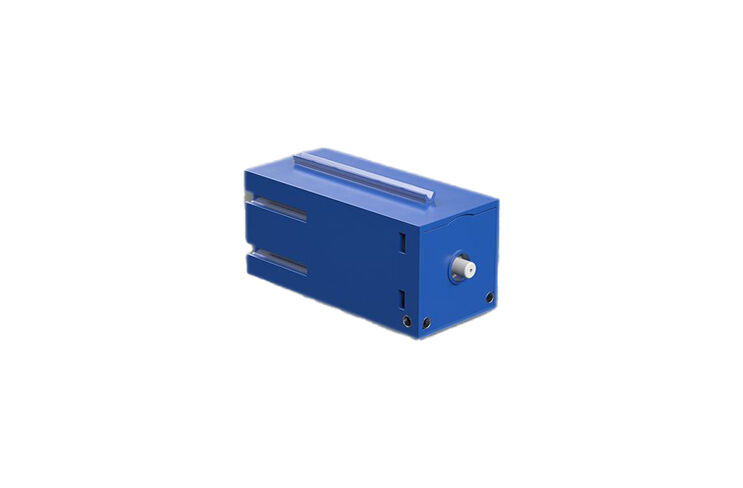

- STEM Pneumatics

Everything to do with pneumatics

Pneumatics was already being experimented with in the third century BC and the enormous versatility of compressed air was discovered. Using 8 models and 29 experiments, STEM Pneumatics teaches the basics of pneumatics and shows, for example, how compressors, pneumatic valves and cylinders and an exhaust air throttle valve work. The concept is rounded off by the comprehensive lesson plans for teachers.

Pneumatics is the name given to the technology used to control and carry out operations in machines using compressed air. Just as with pressurized oil in hydraulic cylinders of large excavators and other construction machinery, large forces and fast movements can also be achieved with compressed air. This offers a whole range of advantages - especially in the children's room and classroom:

For these reasons, pneumatics can be found in countless industrial applications for processing workpieces, filling beverages, packaging, gripping and handling parts and much more.

Pneumatics has a surprisingly long tradition: as early as the third century BC, the Greek mathematician and inventor Ctesibius was already working with compressed air and the machines it made possible. His first pneumatic machine was a pump for lifting water. This was followed by compressed air-based clocks, catapults and organs.

The enormous versatility of compressed air became known and pneumatics was therefore used more and more. Steam engines, steam locomotives, diving with compressed air, painting, airbrush techniques, compressed air sirens, speed measurement with ram jets on airplanes - all of this is part of pneumatics and shows how useful and variable this relatively simple technology can be used.

Today, it is hard to imagine everyday life without pneumatics. It serves countless purposes, from inflating a balloon to the pneumatic hammer in road construction, the easy-to-hold pneumatic impact drill in the household, the suction of air before food is welded in and large industrial plants. A wide field!

Pneumatics is the branch of compressed air technology that deals with the performance of work using compressed air (typically in pneumatic cylinders) and the control of machines designed for this purpose (via valves). This can be divided into the following areas:

Another interesting area of pneumatics is fluidics: switching and controlling with flowing media (gases such as air or liquids). The special feature of this variant is that fluidic valves for logic circuits do not require any moving parts, but instead perform their function solely by cleverly shaping flow channels. It is not the pressure that is the essential signal, but the flow of the medium. With pneumatic fluidics, this works with a pressure of just 100 mbar, requires no oil for lubrication and allows the valves to clean themselves due to the high flow velocity. Only when large forces are required at the end of the control system are the fluidic signals converted into standard pneumatic or electrical signals.

Pneumatics touches on the physical fields of mechanics, kinematics and thermodynamics (compressed air gets warm), fluid mechanics and the mathematical field of logic in logic circuits in pneumatic control systems and therefore Boolean algebra.