- Home

- Toys

- E-Learning

- ROBOTICS Hightech

Download ROBO Pro Coding App

Before you start, you need to download the app. Simply select the appropriate operating system and click on the link:

Download Voice Control

Tell the robot where to go long! Download our Voice Control App and give the robot individual commands:

History

In 1951, Raymond Goertz built a teleoperator arm which made it possible to complete operations, for instance on radioactive material, from a distance.

The industrial robot was officially invented in 1954 by George Devol, who registered for a patent for a programmable manipulator in the USA. Alongside Joseph F. Engelberger, Devol founded the world's first robotics company, Unimation, n 1956.

The company developed the industrial robot Unimate, which was used on a production line for the first time in 1961 at General Motors, to remove and separate injection moulded parts. The first commercially available robot was launched in 1959 by the Planet Corporation. This robot was already suitable for use in completing simple tasks, such as resistance spot welding. However, Planet Corporation's concept was still based on a mechanical controller using cam discs and limit switches, while the Unimate already had a numerical control.

In 1973, the German robotics pioneer KUKA built the world’s first industrial robot with six electro-mechanically driven axes, known as the Famulus. One year later, in 1974, the Swedish company ASEA (today ABB) presented its own fully electric robot IRb6.

Types of robots

The best way to differentiate between different robots is based on their tasks or characteristics.

They can be divided into “stationary robots”, “autonomous mobile robots”, “cognitive robots” and “humanoid robots”.

TXT 4.0 Controller

The TXT 4.0 Controller has a powerful 32-bit Cortex A7 processor, 512 MB RAM of storage space and 4 GB eMMC, three servo outputs and a touch display that supports gestures, and offers a wide range of new functions

Up to nine additional controllers can be connected to one controller as extensions.

Firmware updates can be downloaded online via the fischertechnik cloud. The ROBO Pro Coding software can be used for graphic programming, as well as using the programming language Python.

The software supports the following operating systems: Windows, MAC OS, Linux, iOS and Android. The app can be installed from any app store.

Other features of the TXT 4.0 Controller include:

Sensor - Infrared sensor (track seeker)

The infrared track sensor is a digital sensor used to detect a black track on a white background. The measurement distance is between 5 - 30 mm. The sensor consists of two transmitter and receiver elements

Sensor - Ultrasound sensor (distance measurement)

A distance sensor is a technical component able to measure the distance between itself and an object. Distance sensors work using light, infrared radiation, radio waves or ultrasound, and use different measurement methods. The fischertechnik distance sensor uses ultrasound. Sound spreads as a wave.

An echo is reflected to the ultrasound source, which is then received as a signal and analysed. The difference between the times at which the signal was transmitted and received indicates the distance between the obstacle and the sensor. The range of the sensor is up to 4 m. The numerical value output corresponds to the distance in centimetres.

Sensor - Camera (image and colour recognition)

The camera is a particularly versatile sensor. The image resolution is 1 Megapixel. The images the camera takes can be transmitted to a PC and displayed on the screen. In addition, the ROBOTICS TXT 4.0 Controller can process the images and use them to detect movements, colours and tracks so that the user can control the robotic model. The camera can be focused by turning the lens.

Actuator - LED

A light emitting diode is a semiconductor component that transmits light. It is known as an LED for short. . When electrical current flows through the diode, it emits light. The wavelength (colour of the light) depends on the material of the semiconductor and the doping. The LED emits white light.

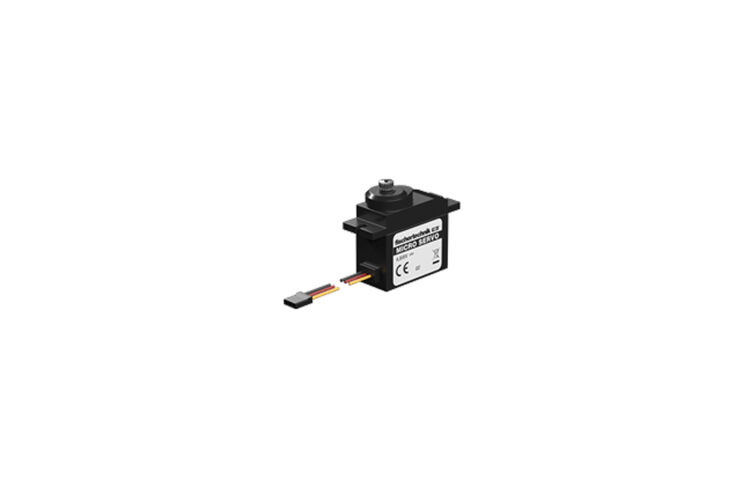

Actuator - Servo motor

A servo motor is a rotary drive or linear drive which allows for precise control of the angular or linear position, speed and acceleration. It consists of a suitable motor, which is connected to a position feedback sensor. Servo motors are used in applications such as robotics, radio-controlled plane or vehicle models or automated production.

Actuator - Encoder motor

At first glance, an encoder motor looks like a normal electrical motor designed for a 9 V voltage and a maximum current consumption of 0.5 ampere.

However, an encoder motor can do much more. In addition to providing a connection to supply power to the motor, they also include a socket for a 3 pin connection cable that can be used with the so-called encoder to assess the rotary motion of the motor. The encoders on fischertechnik encoder motors generate 3 impulses per rotation of the motor shaft. And because the encoder motor also has a gearbox with a transmission ratio of 21.3:1 (read as “21.3 to 1”), one rotation of the shaft from the gearbox is equivalent to 63.9 impulses of the encoder.

The Mecanum wheel is a wheel that allows a vehicle to conduct omnidirectional driving manoeuvres without being equipped with mechanical steering. Sometimes, it is also called a Ilon wheel after its inventor, Bengt Ilon. In contrast to all-wheel drive, the rollers on a Mecanum wheel are at an angle to the main axis.

The wheel was first patented by J. Grabowiecki in 1919.

fischertechnik uses Mecanum Omniwheels, with rollers arranged at a 45° angle. These allow the movable fischertechnik robot to move in all directions, driven by four motors.

And how does it work?

Multiple rotating barrel-shaped rollers are attached on the circumference (the “rim”) of the wheel, most of them at an angle of 45 degrees to the axle of the wheel as a whole. Only these rollers are in contact with the ground. They do not have a direct drive, and can turn freely around their angled bearing axis.

The entire Mecanum wheel, in contrast, is driven by a drive motor such as an encoder motor that can change direction and with variable speed.

Vehicles equipped with these wheels generally have four of them, which are arranged in a rectangle (“car arrangement”).

The axes of the tilted rollers must either point in a star shape to the centre of the vehicle at the contact surface, or all angled axes of the rollers must be on a projected circle (different angles selected for the rollers on the front and rear axles – each +45° or −45° to the axle of the Mecanum wheel).

If this criterion is not observed, then omnidirectional drive forces cannot be generated. Only by arranging the contact surfaces in a circle is it possible for them to turn around their centre point, which is desirable in most applications.

To be best prepared to program the models, you can download an overview sheet on the drive and the direction of rotation of the Omniwheels.